You Need to Know That About Prefab Homes!

Prefab homes are constructed as structures produced in a factory environment and reinforced with galvanized steel. These structures are combined with flexible materials and cement board coating to create a durable, lightweight, and portable house model. Prefabricated houses have a number of advantages, especially earthquake resistance, high thermal insulation, the ability to be produced in special measurements, and easy transportability.

Prefabricated House Advantages:

Price Performance: It is a more economical option than reinforced concrete houses.

Earthquake Resistance: It is durable and almost indestructible thanks to the use of galvanized steel.

Portability: It can be easily moved to another place when desired.

Ease of Integration: The simplicity of systems such as air conditioners,combi boilers, and ready-made air conditioning lines can be found.

Special solvability: Can be designed to a super luxury level with optional features and details.

Ease of Plumbing: Electrical and water installations are prepared, and extra sockets or water lines can be added as desired.

Design Flexibility: It can be added according to details such as verandas and balconies.

Environmentally Friendly: An environmentally friendly structure is provided with recycled products.

Absence of Foundation Problems: There is no need to deal with problems such as digging foundations.

Prefabricated House Prices:

Prices of prefabricated houses vary depending on basic expenses such as material costs and labor. Each house has a standard price, with prices for additional features and requests. Creates and requests measurements and details for projects.

Prefab House Interior Design:

The interior of prefabricated houses is no different from traditional houses. Large televisions can be mounted on the walls, and products such as air conditioners, paintings, and chandeliers can be easily mounted. The interior design can be completely environmentally custom or offer a ready-made design.

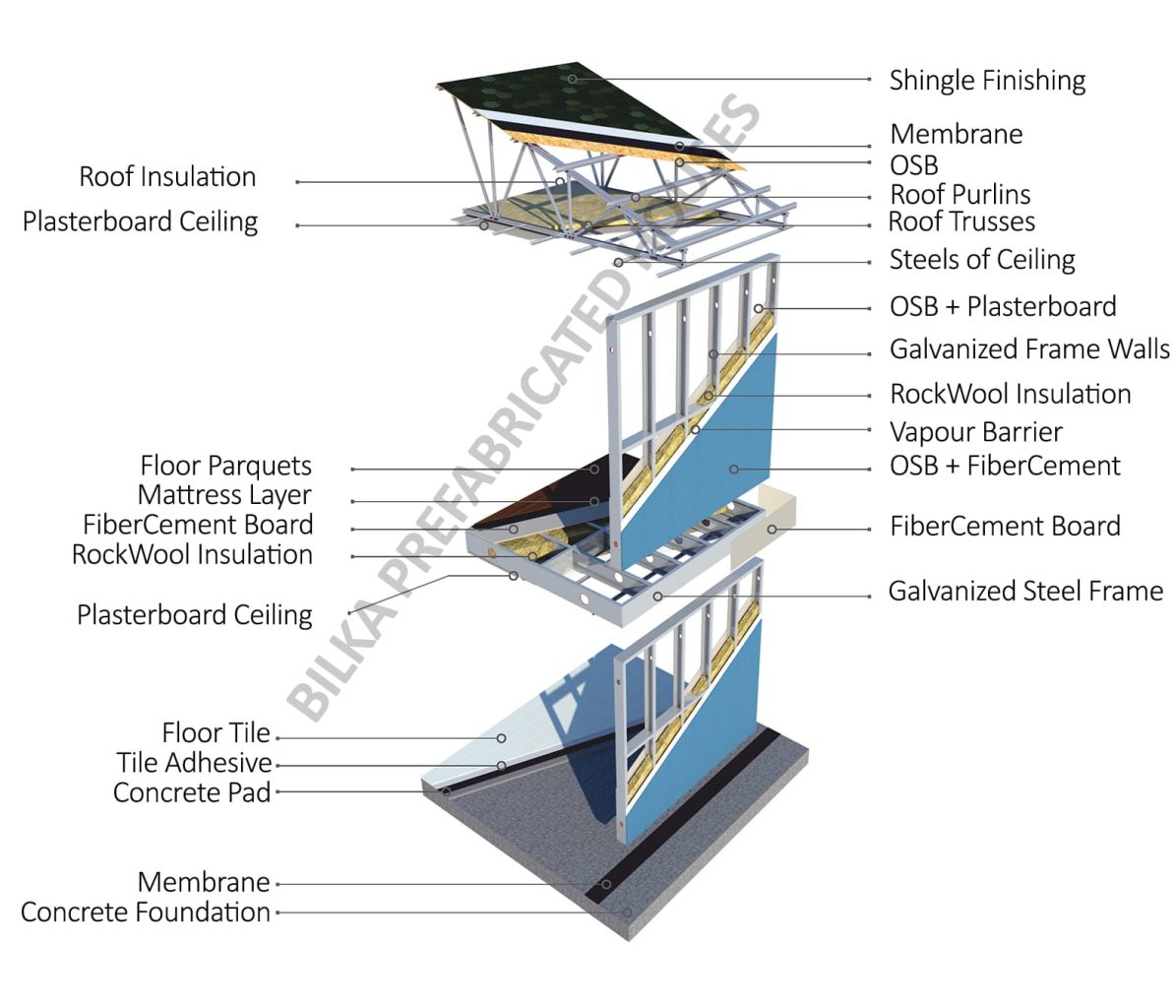

Structure of Prefab Homes:

Galvanized steel used in prefabricated houses is bent and shaped to form the structure of the house. This steel structure makes the house durable. After containing the skeleton, the walls are usually covered with liquid materials such as rockwool and OSB (Oriented Strand Board).

Rockwool is a material that provides sound insulation and heat insulation. OSB is a plate that increases profits. These features enable the placement of the interior of the steel structure and give it strength and durability properties. Moisture barrier is used for waterproofing and preventing moisture

Wall surfaces for the interior are then usually covered with drywall. Drywall is used to create a smooth interior surface and provides a suitable basis for the design of the interior.

A durable and weather-resistant material such as fiber cement is usually used for the exterior of the house. Fibercement sheets are added to the exterior siding, covering the house and providing protection against exterior permanence. This material offers an aesthetic appearance while preserving the abnormality factors of the house.

As a result, the production process of the prefab homes usually begins with galvanized steel fingerprinting, and then continues with the assembly of parts that provide moisture and protection on the interior and exterior surfaces. This process ensures a durable, economical, and useful structure.

Prefabricated houses can be designed in accordance with contemporary living conditions and offer individually solvable features. With these features, they are preferred as economical, durable, and environmentally friendly housing options.